USE CASES

Learn More About Where and How Our Custom Sensors Are Being Used Today

INCISION-FREE SURGICAL ALTERNATIVES

PROBLEM

Spectra Symbol had been contacted by a medical device company from the West Coast about 5 years ago. They were in development of a new device that could change the lives of women who suffer from uterine fibroids. At the time the only solution was to have a surgery to remove the growths or worse, to have a hysterectomy. The aftermath of the procedure left women in pain and like many surgeries, on a light duty lifestyle for a couple of weeks or longer. For some, it would even eliminate the ability to have children. They knew there was something that could be developed to better the lives of many women worldwide and they were determined to be the ones to do it.

SOLUTION

Spectra Symbol has been an integral part for medical device manufacturers for many years as a source for low profile, low cost sealed sensors. Our sensors offer absolute position all while keeping a low profile form factor to fit into tight spaces and low cost to accommodate the need for disposable devices. Spectra Symbol worked together with the customer’s engineering team to create a custom sensor that would give the competitive edge in their device and to give women another option for treatment.

Within a few months of initial contact, Spectra Symbol had created a custom sensor that our customer could start testing. After months of in-house testing of the complete device they were able to start clinical trials to prove the device and apply for FDA testing and approval. To date, this devices has a CE Mark and is approved for use in Europe. Testing for USA FDA approval is still in process. This device is an incision free, uterine preserving alternative to the removal of fibroids and hysterectomy. This device gives women the treatment they need and offers them the option to have children.

REAL-TIME PRODUCT MANAGEMENT

PROBLEM

Medical, Pharmaceutical and Industrial OEMs often need electronic feedback to track merchandise real-time. A certain customer designed and operates industrial vending machines but was having difficulty tracking their stocked merchandise. The vending machines were mechanically configured similar to traditional vending machines with a large spring and “pusher” that applied pressure to keep product to the front of the machine.

SOLUTION

Spectra Symbol designed a custom length and width version of the SoftPot, also known as our ThinPot, that fits very well under the spring due to the low form-factor of the sensor. We connected a wiper, or actuator, to the pusher portion of the vending machine arm so that as merchandise is purchased, a real-time position signal is recorded and streamlines merchandise management. Other applications include pharmacy drugs, sealable or stocked items, absolute positioning on hand-held medical devices (dental, surgery, etc.)

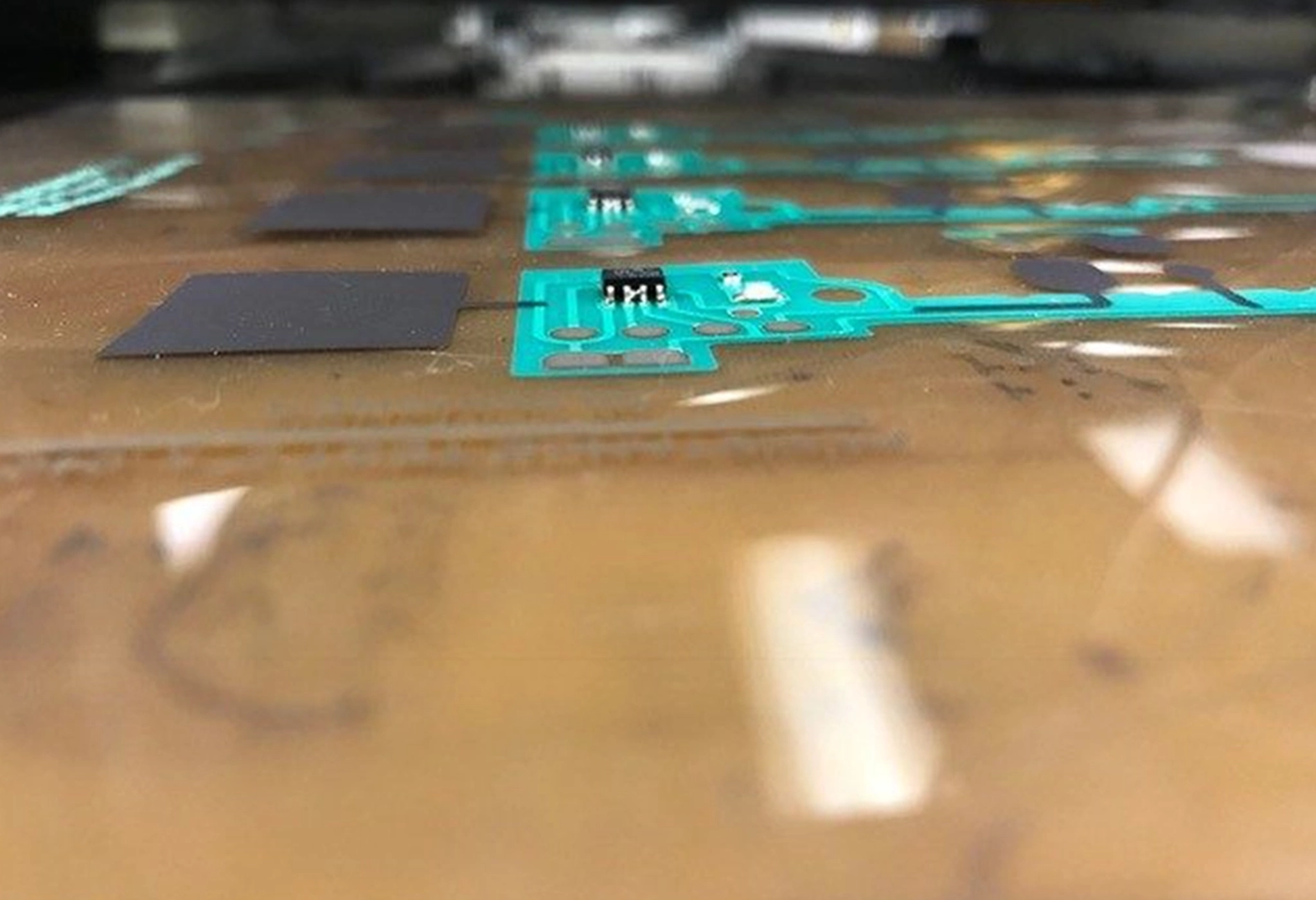

ThinPot with custom lengths, extra narrow construction, and with 3M adhesive on one side to adhere to the merchandise tracks.

EFFICIENCY IN WELL SITE MONITORING

PROBLEM

Above ground storage tanks for well sites collect oil and water that is pumped from the ground. Most new wells that are drilled have separators He was very concerned about their well site pump jacks shutting down due to various factors, especially in the winter, but all the other options to monitor his pumps proved too cost-prohibitive. As a result, during the winter months they would drive twice a day to visually inspect each of their pumps just to make sure that they were running. If they found one that wasn’t running, it could have stopped hours earlier making it impossible to res pond before the situation became costly.

They realized that even their costly process of manually tracking pumps twice a day was not enough to avoid costly downtime.

SOLUTION

Kodiak Instruments (a Spectra Symbol company) provides a reliable remote pump monitoring solution that includes a wireless motion sensor and a solar-powered gateway. The monitor tracks the motion of the pump and can be set to alert managers in real-time by text and email if their pumps unexpectedly stop operating.

The pump monitors have strong magnetic feet attached to the bottom of the housing and fit in one hand. Please see this tutorial that shows how easy the pump sensor is to install. The monitor is attached to the moving arm of the pump, depending on what kind of pump jack it is. 120 data points are taken in a single minute tracking the motion, speed, and consistency of the pump and transmitted through Spectra’s gateway to our database. Customers can access the real-time data via their mobile device or desktop.

Within days of installing the pump monitor, the pump jack engine was flooded with excess fluid buildup from the natural gas chambers which caused the pump to fail. The field manager was alerted and was able to respond within the hour. The spectra symbol IoT software database was able to provide data points that the customer used to compared the final few rotations to the average speed duration. A typical failure pattern was identified and can be used for predictive analytics which can alert field managers that the pump is acting abnormally before it shuts down.

SPECTRA SYMBOL QUALITY SAVES OEM CLIENTS MONEY

PROBLEM

One major customer is having supply-chain issues for three reasons:

1. Quality is uncontrolled in Asia, hard to communicate exact needs, the specifications required of a Class-3 Medical Device

2.Delivery is slow and comes in huge batches, causing large inventory swings and stock-out problems in the market

3.Cost increases with bad quality, and with wage changes in Asia

SOLUTION

The customer brought their challenges to Spectra Symbol and we were able to address each of their concerns:

By improving the manufacturing process, their product failure modes went away.

Delivery is now Just-In-Time, available from our US-based factory to anywhere in the continental USA immediately, which not only stops stock-out problems, but also allows the Customer to avoid carrying huge inventory stockpiles.

Cost was able to remain competitive. Change-over costs were very low because Spectra Symbol tooling and NRE for each job is typically $3K-$5k. Long-term pricing is competitive because of TPS/Lean flow technology which allows Spectra Symbol to compete world-wide.

Technology used includes semi-automated printing and curing, SMT (Surface Mount Tech.) line, which deposits the microchips and resistors necessary for the specialty circuit, and a dedicated “White Room” for cleaner medical-grade applications.